How to Choose a Japanese Hand Plane: The Kakuri Difference

Why Use a Hand Plane? (Hand Planes vs. Electric Planes)

|

Hand Planes |

Electric Planes | |

|---|---|---|

|

| |

|

Pros | ||

|

| |

|

Cons | ||

|

|

Why Use a Japanese Hand Plane? (Japanese Planes vs. Western Planes)

|

Japanese Planes |

Western Planes | |

|---|---|---|

|

| |

|

Pros | ||

|

| |

|

Cons | ||

|

|

A Little Story About Japanese Planes

Like other Japanese-made tools, Japanese planes (wa-kanna) are known for the sharpness of their "blades." However, an interesting aspect of planes is that many factors determining their performance lie in the body (wood). No matter how sharp the blade is, it's useless if it doesn't make proper contact with the wood.

The wooden body of the plane constantly changes due to daily humidity. Only by adjusting the plane to the best condition each time you use it can you bring out its true performance. While it may seem like a tedious task, mastering this process allows you to create a mirror-like smooth cutting surface that cannot be achieved with other tools.

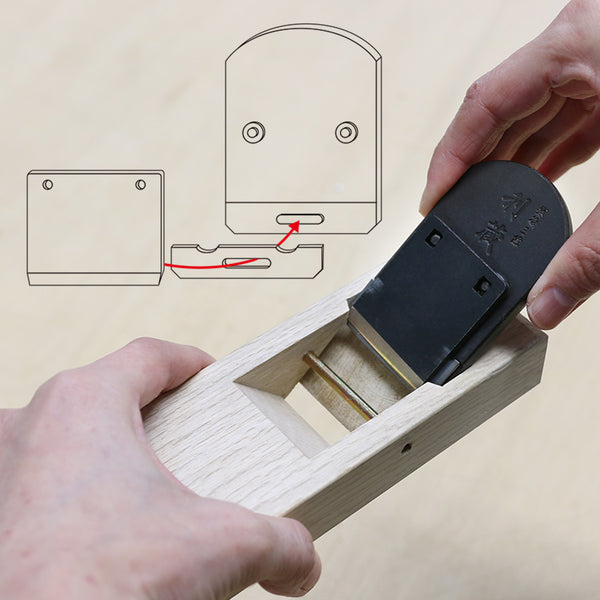

About Double-Blade Planes

Traditional planes had only one blade, making it difficult to cut against the grain. That's why double-blade planes, which use an additional blade called "chip breaker" to prevent tear-out, have become mainstream. At Kakuri, we want beginners to use our planes with minimal mistakes, so almost all our planes are double-blade planes.

About Kakuri Planes

To make them accessible to beginners, our planes are designed to be affordable while maintaining high quality. The blades are made from carefully selected materials, heat-treated, and hand-polished by Japanese craftsmen. The bodies are meticulously crafted by woodworking artisans, who match each one to the slight variations in blade size.

Types of Planes

|

Product Name |

Flat Plane |

Spare Blade Type Plane |

Chamfer Plane |

Ebony Mini Plane |

Rabbet Plane |

Double Corner Rabbet Plane |

Compass Plane |

Sole Flattening Plane |

|---|---|---|---|---|---|---|---|---|

|

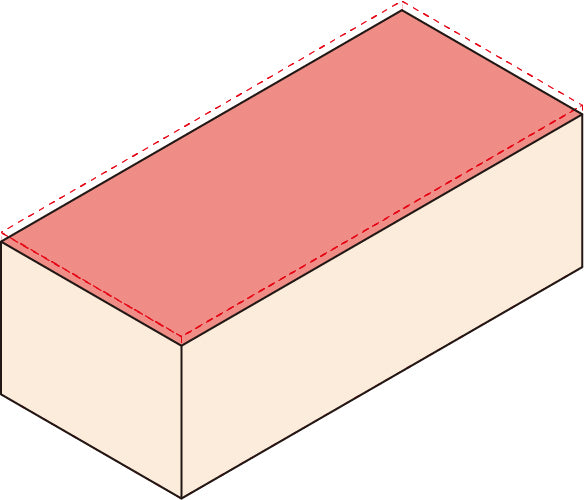

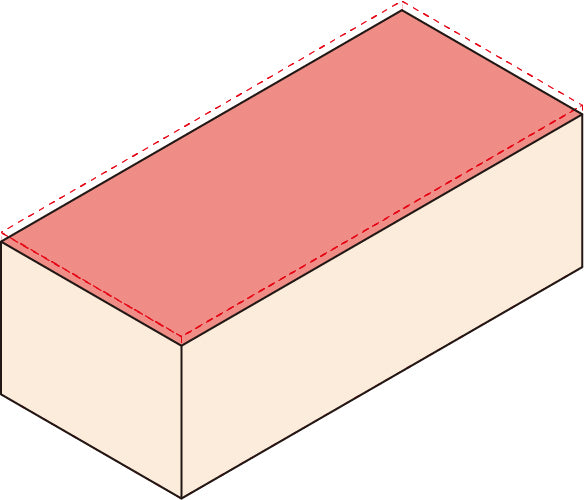

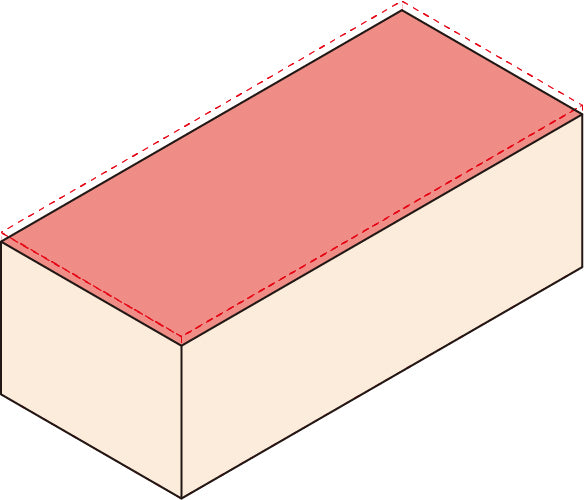

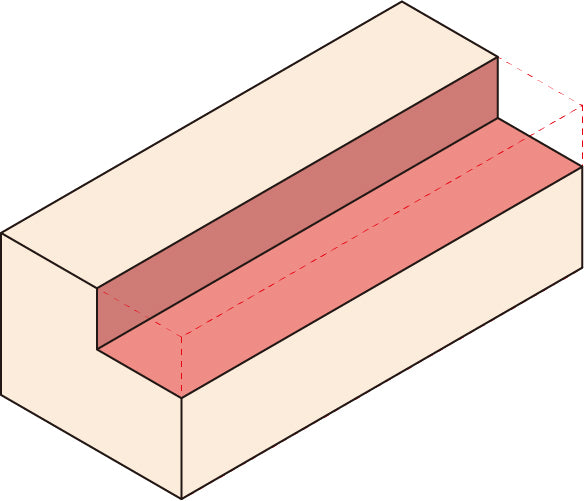

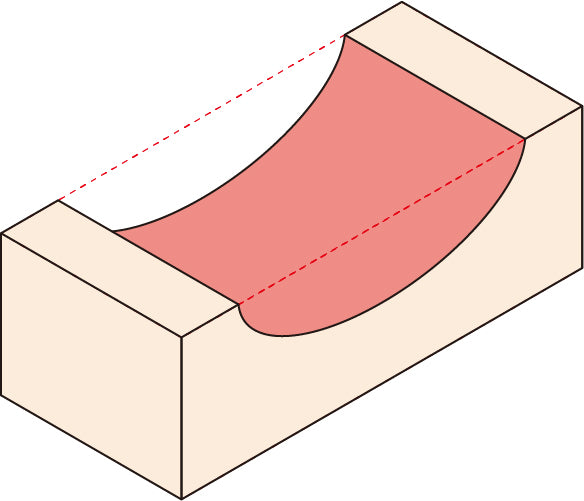

Finished look |

|

|

|

|

|

|

|

|

|

Purpose |

Used for flattening surfaces and edges of wood. Size varies depending on the job:

|

Similar to a flat plane. |

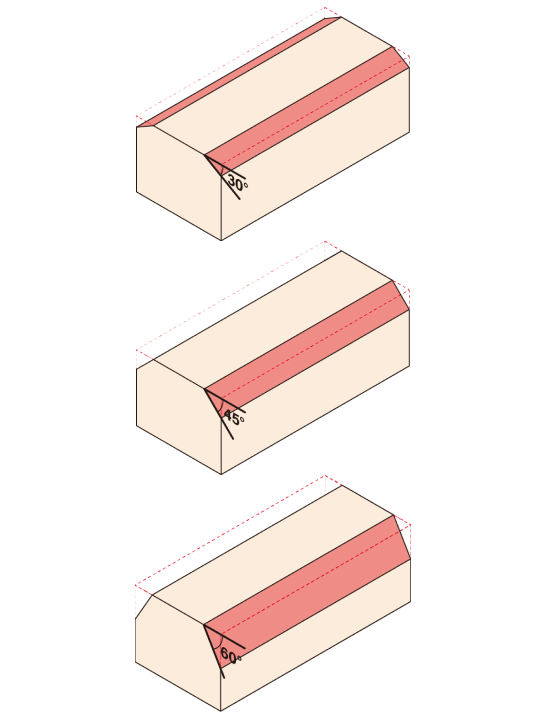

Used for beveling wood surfaces at specific angles. |

Small plane for fine, detailed work. Also used for beveling leathercraft edges. |

Used for cutting grooves in wood. |

Used for cutting edges and inner corners of wood. |

Used for cutting curved surfaces. |

Used for adjusting the bottom (base) of a plane. |

|

Features |

|

Replaceable blade |

Angle guide included |

|

Designed to fit in groove spaces |

Blades on both sides for cutting edges |

Curved body |

Vertical blade |

|

Advantages |

|

Easily restore sharpness |

Can bevel at 30°, 45°, and 60° angles |

|

Can cut grooves of a consistent width (not possible with a flat plane) |

Can cut inner corners of wood (not possible with a flat plane) |

Can cut curved (concave) surfaces of wood (not possible with a flat plane) |

Can cut wood fibers at a consistent angle (compared to cutting with a chisel) |

|

Benefits |

|

Time-saving; maintain sharpness without sharpening tools or skills (less likely to fail) |

Easily bevel frames or boxes |

|

Easily cut long grooves, like those for rails (if not available, chisels are used) |

Easily create stepped joints, like in joinery (if not available, chisels are used) |

Easily finish curved surfaces, like chair legs (if not available, files are used) |

Can neatly and stably adjust the base |

|

Additional Info |

Recommended for beginners who lack the confidence to sharpen themselves or do not have time to sharpen. |

Our ebony small plane has a unique design with superior sharpness compared to similar products. |

Our product uses a laminated blade for better sharpness and easier sharpening compared to all-steel blades. |